Advanced Fatigue Monitoring

Are you confident that your operators are alert and safe throughout their shifts? Are you worried their fatigue can lead to dangerous high-risk behaviors that may put your entire operation at risk?

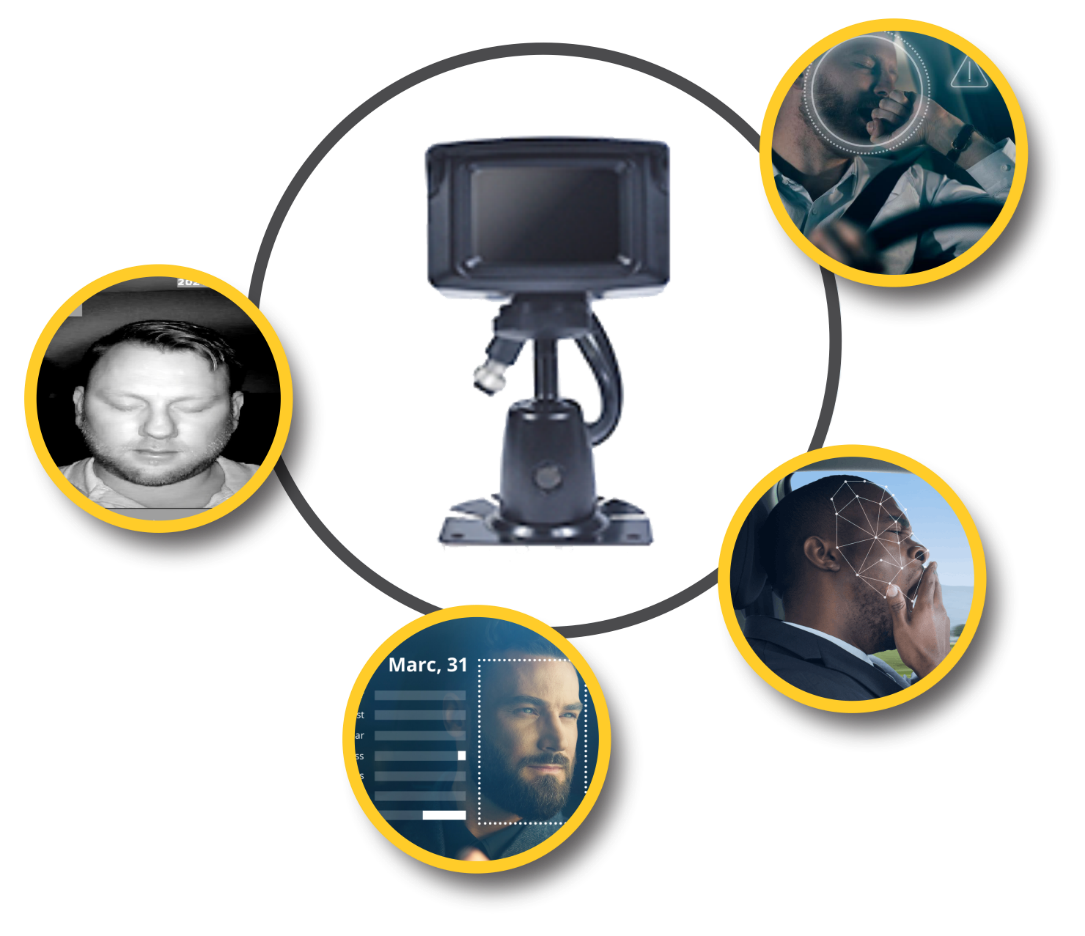

That’s where our Fatigue Monitor comes in. As a class-leading in-cab behavior monitoring system, it’s designed to detect various high-risk behaviors using advanced in-cab sensors. When an issue is detected, operators receive a suggestive audible warning, while the Mine Safe control room evaluates events and communicates valid incidents to the responsible person on-site. Seamlessly integrating with the CPS RTSMS, this system ensures that fatigue is managed proactively, keeping your operations safe and efficient.

Description

Key Features:

- Advanced sensor technology: The camera and infrared sensors detect the operator’s face and pupils, triggering a fatigue alarm when signs like unrecognizable pupils, head dropping, yawning, looking away from the road, smoking, or using a phone are detected, with sensitivity and alarm duration customizable for specific applications.

- Integrated sensor camera: By combining sensor and camera technology into a single unit, we ensure the most accurate results and prevent tampering, keeping operators accountable and Mine Safe’s control room informed at all times.

- Configuration of all parameters: The time frame of how long pupils are not recognizable before an alarm is initiated, and the delay between alarms are configurable. Operators are unable to interfere with or change the system parameters.

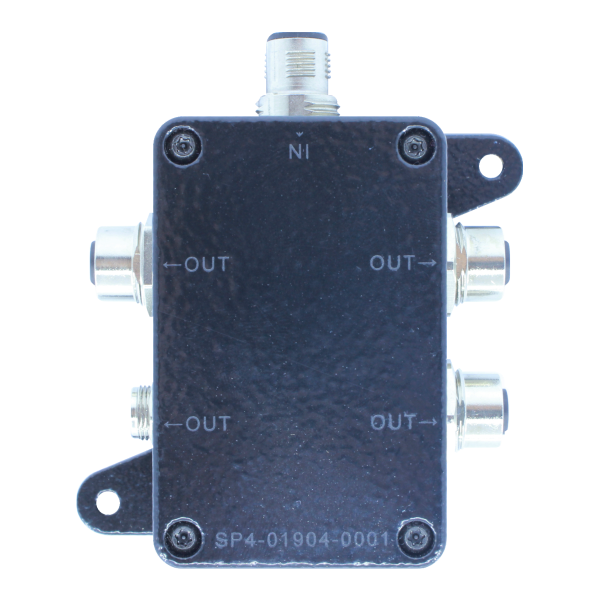

- Enhanced coverage: Connect up to four wide-angle night vision color cameras to the system for enhanced coverage. All footage is recorded directly on the in-cab device for thorough documentation.

- Seat vibration motor: The CPS Fatigue Monitoring System can activate a vibration in the operator’s seat upon detecting fatigue, providing a physical alert alongside the in-cab warning to address unsafe behavior.

- Flexible mounting solution: Choose from a range of mounting brackets, including non-invasive suction cups or permanent fixtures, to securely install equipment in your machine’s cab.

- Trip data tracking: The system provides real-time location updates, location history, trip data, and mileage tracking for comprehensive monitoring and reporting.

- Real-time incident reports: Sent in real-time to the responsible supervisor on-site. The report includes machine identification, location, incident type, video evidence, date, time, vehicle speed, and pictures available from the Mine Safe control room.

- Weekly reports: Include incident summaries per machine, lists of true positives, overspeed and mileage reports, and trend analysis per machine and business unit.